Industrial automation and control systems have revolutionized the way manufacturing processes are carried out in various industries. These systems have become an integral part of modern manufacturing facilities, enabling companies to increase efficiency, improve productivity, and reduce costs. In this article, we will explore the key product features of industrial automation and control systems and how they are transforming the manufacturing landscape.

2. Human Machine Interface (HMI): HMIs are user-friendly interfaces that allow operators to interact with the automation system. These interfaces provide real-time data on the status of the manufacturing process, allowing operators to monitor and control the system effectively. HMIs can display information in the form of graphs, charts, and alarms, making it easier for operators to identify and address any issues that may arise during production.

3. Supervisory Control and Data Acquisition (SCADA): SCADA systems are used to monitor and control industrial processes from a centralized location. These systems collect data from various sensors and devices in the manufacturing plant and provide real-time information to operators. SCADA systems can also be used to analyze historical data, identify trends, and optimize production processes. By providing a comprehensive view of the manufacturing process, SCADA systems help companies improve efficiency and reduce downtime.

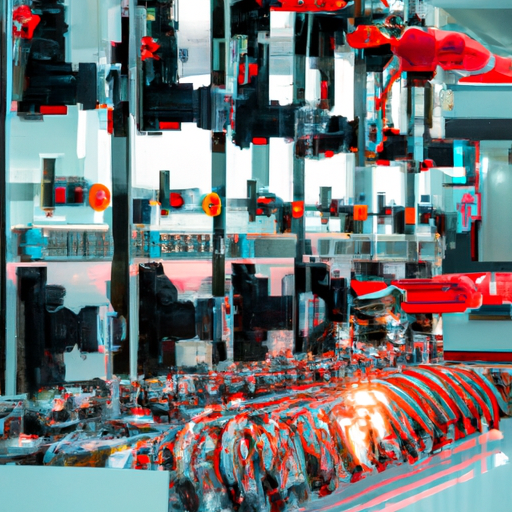

4. Industrial Robots: Industrial robots are automated machines that can perform a wide range of tasks in manufacturing plants. These robots are equipped with sensors and actuators that allow them to perform precise and repetitive tasks with high accuracy. Industrial robots can be used for various applications, such as welding, painting, assembly, and material handling. By incorporating robots into the production line, companies can increase productivity, improve quality, and reduce labor costs.

5. Motion Control Systems: Motion control systems are used to control the movement of machinery and equipment in manufacturing plants. These systems can regulate the speed, position, and acceleration of motors and actuators to ensure smooth and precise operation of the production line. Motion control systems can be integrated with PLCs and HMIs to provide a comprehensive solution for controlling and monitoring the manufacturing process.

6. Industrial Networking: Industrial networking systems are used to connect various devices and equipment in the manufacturing plant. These networks enable seamless communication between different components of the automation system, allowing data to be exchanged in real-time. Industrial networking systems can be wired or wireless, depending on the specific requirements of the manufacturing process. By implementing industrial networking solutions, companies can improve connectivity, enhance data sharing, and streamline operations.

7. Safety Systems: Safety is a top priority in industrial automation and control systems. Safety systems are designed to protect workers and equipment from potential hazards in the manufacturing plant. These systems include emergency stop buttons, safety interlocks, and safety sensors that can detect dangerous conditions and shut down the production line if necessary. By implementing robust safety systems, companies can ensure a safe working environment for their employees and prevent accidents and injuries.

In conclusion, industrial automation and control systems offer a wide range of features that can help companies improve efficiency, increase productivity, and reduce costs in manufacturing processes. By incorporating PLCs, HMIs, SCADA systems, industrial robots, motion control systems, industrial networking, and safety systems into their operations, companies can achieve greater automation and control over their production processes. With the rapid advancements in technology, industrial automation systems are becoming more sophisticated and versatile, enabling companies to stay competitive in today's fast-paced manufacturing industry.